This document, created by Anass SABANI, provides a comprehensive guide on calibrating equipment using SAP Plant Maintenance (PM) module. It covers the overview of calibration, the process flow for calibrating test equipment, and a step-by-step walkthrough of the calibration process via SAP transactions.

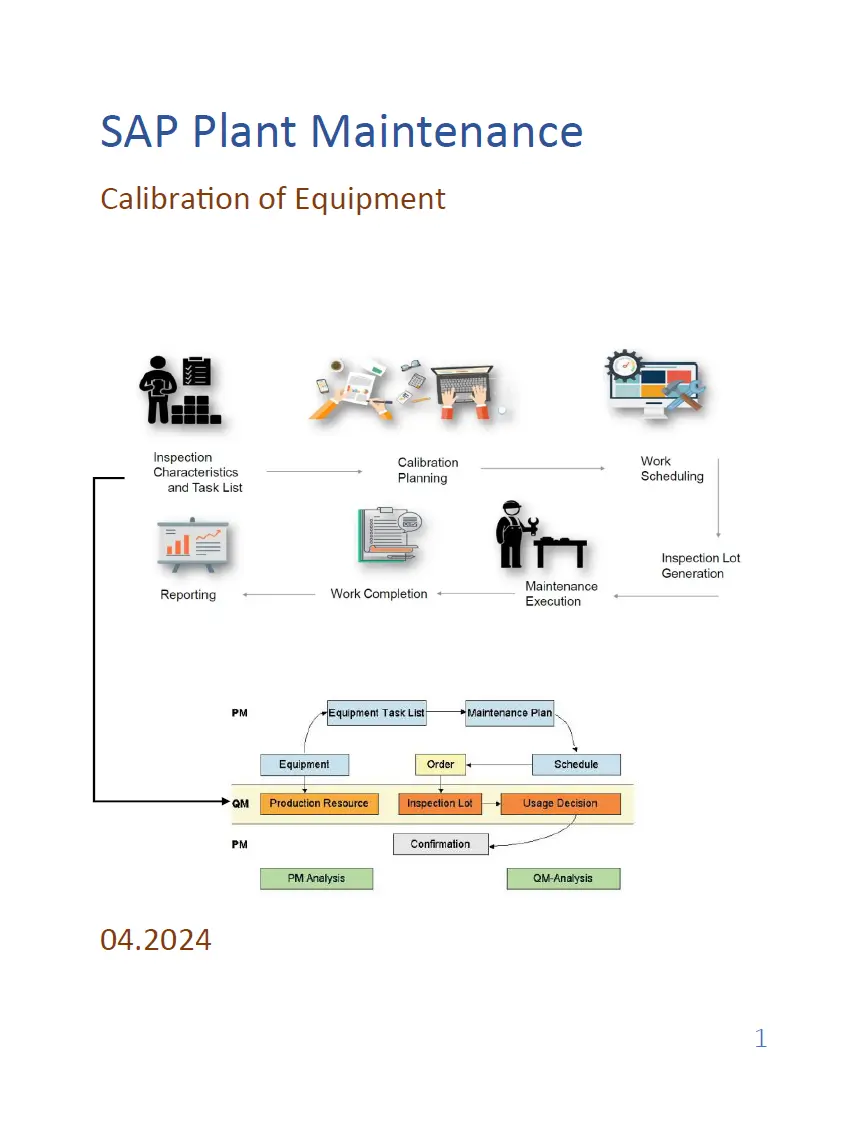

The aim is to ensure measurement devices achieve accurate and precise readings through a carefully planned and executed calibration program. The calibration inspection process involves inspecting equipment specified in a maintenance order, recording results, evaluating each piece, and making a usage decision.

The document leverages SAP’s test and measurement equipment management functionality across PM and QM modules, utilizing the classification system to define equipment dimensions. Overall, it serves as a valuable resource for maintaining precision through effective equipment calibration management within SAP.

Key sections covered:

- Calibration Overview

- Calibration of Equipment Process Flow

- Calibration of Equipment Step-by-Step via SAP

- Process Calibration Test Template

- Transactions List for Calibration Maintenance in SAP PM

- Glossary of key terms (MICs, inspection types, inspection points, inspection lots)

Download – Calibration of Test Equipment in SAP PM: Step-by-Step Guide